The Main Core Materials of the 4th Industrial Revolution

Essential for data management and electric vehicles

Stimulating the development of cheap and powerful permanent magnets worldwide

Magnets are familiar as childhood toys. However, it is also a ‘national core future material’ which is essential in the era of the 4th industrial revolution. It is essential for most high-tech fields such as electric vehicle drivers and data storage and reading. Scientists around the world are researching making magnets stronger, more efficient and cheaper. In terms of current technology, rare earth elements, a key conflict between the technological hegemony of the United States and China, are the main materials, so new technology research is essential to ensure a stable supply chain.

What is a Magnet?

As it already existed in nature, it was used as a compass. William Gilbert (1544-1633), an English physician, assumed that the earth was a magnet because the north pole pointed north, which was later recognised. However, the Earth’s magnetic field changes between the north and south poles every few hundred thousand years, and the magnetic field is different for each location. The exact cause of the earth being magnetic is not yet known. The Danish scientist Hans Christian Oersted (1777-1851) discovered that a magnetic field was created when an electric current passed through it, and Michael Faraday (1791-1867), a famous British chemist and physicist who discovered benzene, made electricity when magnet had discovered that

The magnetic field is the source of force for electrons that rotate and rotate around the nucleus. Basically the same as the present. In other words, if electrons receive energy and are pushed out of their original position and flow, current is current, while electrons rotate and turn, creating a magnetic field. So basically, all atoms can be considered to have magnetic properties. They are divided into ferromagnetic, paramagnetic, and diamagnetic in order of strength. The stronger the magnetic force, the better the rotation of the electrons aligned in the same direction, and the weaker the stronger the heating. However, depending on the nature of the atom, there are materials that are not magnetic at all, such as copper or plastic. What determines the strength of magnetism is the temperature and the distance between atoms. The higher the temperature, the weaker the magnetism and the different movements of the electrons. The closer the temperature is to absolute zero (273 degrees below zero), the more constant the movement of electrons becomes, and as they become aligned, they become magnetic. The distance between atoms also has an effect. This is because the alignment between electrons is easy when the distance between atoms is not too close or too far.

Scientists have been trying to create artificial permanent magnets for over 100 years. In the 1940s, ferrite made of iron oxide was developed as the main material, Alnico made of aluminum, nickel, and cobalt in the 1950s, and samarium-cobalt (Sm-Co) magnets in the 1970s. However, there were limitations to commercialization through mass production and supply as it was made of cobalt, an expensive and rare metal. Then, in 1981, Masato Sagawa of Japan developed a powerful and cheap neodymium (Nd-Fe-B) magnet, making it possible to use magnets in all kinds of industrial products. Iron was mixed with the rare earth elements neodymium and boron. Iron was originally known as a material whose atoms were too close together to make strong magnets. Sagawa managed to create the strongest magnet ever by inserting light, cheap and small boron atoms between iron atoms and found the golden ratio that can cause the alignment of electrons with neodymium. However, the disadvantage of this magnet is that its performance deteriorates at high temperatures (200 degrees Celsius). Incorporating another rare earth element, dysprosium (Dy), can improve this.

![[과학을읽다]'Spintronics' changes the future... Magnets influence national fortunes](https://i0.wp.com/cphoto.asiae.co.kr/listimglink/1/2023060215085951926_1685686139.jpg?w=800&ssl=1)

Spintronics is changing the future

Spintronics is the study of what happens when electrons with spin move. In other words, it is a task to study various changes that occur when current flows through a magnet and apply them to advanced technologies such as computer hard disks and semiconductors. In the 1980s, with the advent of nanotechnology, which studies extremely fine materials, research began in earnest. Scientists who could manipulate atoms tried to make artificial magnets by stacking atoms layer by layer. At first, using the principle that a strong magnet can be made when the distance between atoms is widened, atoms were stacked one by one between magnets. Until then, the magnet seemed to be getting stronger and they were succeeding. However, when the atoms were placed in two layers, a phenomenon suddenly occurred, where the upper and lower magnets exchange positions with each other, and interlayer exchange bonds and repetitions occurred. This is the ‘Giant Resistive Magneto Effect’ discovered in 1988 by Peter Grünberg and Albert Fer. The magnetic head that applies this is the core of modern computer hard disk technology. The hard disk disk stores digital information as pole N 1 and pole S 0. At the end of the magnetic head, two small magnets are placed vertically. The upper magnet is fixed with the N pole, and the lower magnet contacts the N pole and the S pole of the lower disk alternately, repeating parallel and anti-parallel phenomena. At this time, resistance appears and then decreases, through which digital data can be read. Professor Kim Kap-jin from KAIST’s Department of Physics said, “The core of the 4th Industrial Revolution is data, and the medium to store and read it is the magnet.” It happens,” he explained.

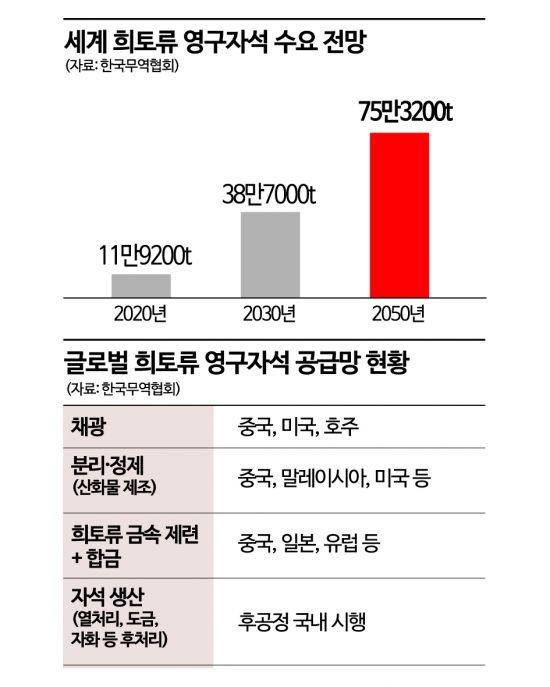

national key material for the future

The rare earth neodymium currently used in commercial neodymium magnets is mainly extracted from monazite and pastnasite through a complex process. It is very polluting and labor intensive, so as with other rare earths, China produces most of the world’s supply. As the competition for technological hegemony between the United States and China intensifies and the global supply chain becomes unstable, the need to replace or supplement Chinese neodymium is also growing. Korea also plans to develop a rare earth-reducing permanent magnet material technology that can replace 30% of neodymium in permanent magnets with cheap cerium (Ce) through a national research and development project in 2021, and commercialize it soon .

In this regard, in March, the research team of the Korea Material Research Institute revealed the specific details. It is said to have succeeded in developing a rare-earth-reducing permanent magnet material technology that can reduce the use of neodymium (Nd), an expensive rare-earth element, by about 30% and realize the same level of performance as commercial. magnets (grade 42M). Instead of the existing process, the melt spinning method and the hot deformation method, which can be processed at a very fast cooling rate, were applied to produce rare earth precursors and permanent magnets, respectively. As a result, they have managed to optimize the microstructure of the magnet by preventing the formation of unwanted magnetic particles in the magnet. Through this, it was possible to improve the residual magnetization and the coercive force at the same time, which are the main characteristics of permanent magnets. The domestic market for rare earth permanent magnets for high efficiency motors reaches 186 billion won a year from 2021, but almost all of them are imported from abroad. It is a technology that can be used for electric vehicles, drones, flying cars, and electric ships.

Kim Tae-hoon, a senior researcher at the Materials Research Institute, said, “Among the materials that determine motor performance, permanent magnets have the greatest effect, and the stronger the magnet, the better the performance .” “We started researching technology to localize rare earth permanent magnets, but our start was a bit late.” He continued, “Even if a technology is developed at the laboratory level, it often does not work well at the mass production stage.” he encouraged.

Correspondent Kim Bong-soo bskim@asiae.co.kr