UNIST Professor Develops Method for Manufacturing Eco-Friendly Fluorocarbons for Lithium-Ion Battery Anodes

An Advanced Solution for Battery Anodes

A domestic research team led by Professor Jong-Beom Baek from the Department of Energy and Chemical Engineering at Ulsan National Institute of Science and Technology (UNIST) has revolutionized the production process of fluorocarbons, resulting in improved performance, stability, and eco-friendliness of lithium-ion battery anodes.

A Breakthrough Manufacturing Process

Professor Baek’s team has developed a groundbreaking technology that safely and easily synthesizes fluorinated carbon by reacting Teflon (PTFE) with graphite. This innovative method, known as mechanochemical ball milling, significantly enhances the storage capacity and electrochemical stability of the anodes, surpassing the performance of graphite by 2.5 times.

In the conventional manufacturing process, the use of hazardous compounds such as fluorine gas (F2) and hydrofluoric acid (HF) pose serious safety risks, increasing production costs and necessitating complex manufacturing facilities for large-scale production.

Pioneering a Safe and Efficient Way

To address the safety concerns, the research team devised a solid-state fluorination technology, utilizing Teflon as a key component. Teflon, known for its non-stick properties on frying pans, exhibits low friction and chemical stability. When subjected to sufficient energy, a radical formation reaction occurs, resulting in the formation of fluorocarbons that strongly adhere to the graphite surface and edges.

The fluorocarbons produced through this solid-state reaction exhibit superior storage capacity and electrochemical stability compared to conventional graphite anodes. At low charging rates of 50 mA/g, the storage capacity reaches 951.6 mAh/g, which is 2.5 times higher than graphite. Furthermore, even in high charging rates of 10,000 mA/g, the storage capacity reaches an impressive 329 mAh/g, which is up to 10 times higher. After conducting over 1,000 charge/discharge tests at a charging rate of 2,000 mA/g, the fluorocarbon anodes maintained 76.6% performance, whereas the performance of graphite anodes declined to 43.8%.

Promising Applications and Future Directions

Jang Bu-jae, the first author of the study and a researcher at UNIST’s Department of Energy and Chemical Engineering, emphasized that the study not only provides a safe method for fluorination but also opens up possibilities for solid-state reactions. He further expressed that this technology can be applied to various electronic devices’ electrode materials, enabling safe and straightforward mass production.

Professor Baek Jong-beom highlighted the significance of this study in expanding our understanding of commonly seen materials and the potential to develop new materials using the principles of solid-state reactions.

The research received support from the UK brand of Ulsan National Institute of Science and Technology, the Carbon Neutrality Committee, the Ministry of Science and ICT, and the Leader Research Project of the Korea National Research Institute.

The results of this groundbreaking research were published online on July 27 in Advanced Functional Materials, a renowned international academic journal in the field of energy and materials.

Copyright © Industry News. Unauthorized reproduction and redistribution prohibited.

UNIST Professor Jong-Beom Baek’s team synthesizes fluorocarbons using Teflon… Electrode materials can be applied

[인더스트리뉴스 이건오 기자] A domestic research team has developed a fluorocarbon manufacturing method that improves the performance, stability and eco-friendliness of lithium-ion battery anodes.

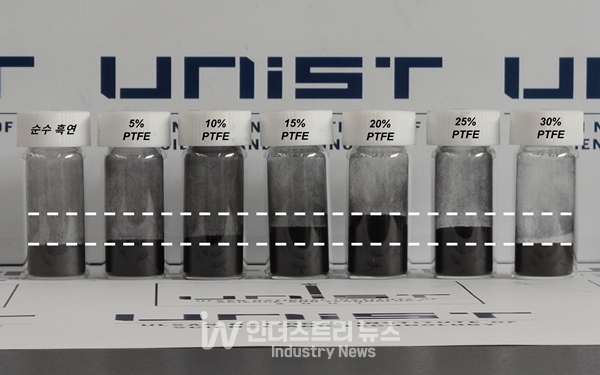

Fluorocarbon manufacturing process by mechanochemical ball milling [자료=UNIST]

UNIST Department of Energy and Chemical Engineering Professor Jong-Beom Baek’s team developed a technology that can safely and easily synthesize fluorinated carbon by reacting Teflon (PTFE) with graphite. Through the ball milling method, a representative reaction induction method of mechanochemistry, storage capacity and electrochemical stability was confirmed 2.5 times better than graphite.

Compounds such as fluorine gas (F2) and hydrofluoric acid (HF) required for the production of fluorocarbons are known as very dangerous compounds due to their high reactivity and corrosiveness. It can paralyze the body or cause death, which increases the cost of manufacturing facilities for large-scale production.

Performance evaluation of lithium ion battery anode with manufactured fluorocarbon [자료=UNIST]

One of the officers of the research team said, “As a means of stimulating a safe and easy fluorination reaction, we devised a fluorination technology using solids. It is a high molecular compound”.

Teflon, which is also used as a coating agent for frying pans, reduces surface friction and is chemically stable, so it is not used as a general reagent. Through an experiment, the research team confirmed that when an energy stronger than Teflon can withstand is received, the chain of molecules is broken and a radical formation reaction occurs. Through various methods of analysis, it has been proven that the molecular complex created in this process reacts with graphite and sticks to the surface and edges to form fluorocarbon.

Fluorocarbons produced by solid phase reaction showed better storage capacity and electrochemical stability than graphite. At a low charging rate of 50 mA / g, the storage capacity (951.6 mAh / g) was 2.5 times higher, and at a high charging rate of 10,000 mA / g, the storage capacity (329 mAh / g) was up to 10 times higher than graphite. Even in more than 1,000 charge/discharge tests at a charging rate of 2,000 mA/g, graphite maintained 43.8% performance, while fluorocarbon maintained 76.6% performance.

Fluorocarbon materials manufactured by a true mechanochemical ball milling process [자료=UNIST]

UNIST professor Baek Jong-beom (left), first author Jang Boo-jae (right)

First author Jang Bu-jae, a researcher in the Department of Energy and Chemical Engineering, said, “This study conducted an experiment on the topic of safe fluorination, but in fact, the most important thing to consider is to suggest the direction and possibility. of solid state reactions.” In addition, it can be applied to electrode materials for various electronic devices, enabling safe and easy mass production.”

In addition, Professor Baek Jong-beom from the Department of Energy and Chemical Engineering said, “It was a study that allowed for new considerations on materials that are commonly seen around us.” If the principle of the solid phase reaction is well established, new materials can be developed that could not be made before.”

This research was carried out with the support of the UK brand of the Ulsan National Institute of Science and Technology, the Carbon Neutrality Committee, and the Ministry of Science and ICT and the Leader Research Project of the Korea National Research Institute. The results of this research were published online on July 27 in Advanced Functional Materials, an international academic journal in the field of energy and materials.

Copyright © Industry News Unauthorized reproduction and redistribution prohibited

#Domestic #researchers #developing #fluorocarbon #manufacturing #method #improves #battery #anode #performance #stability