Starting with OpenAI’s ChatGPT, the artificial intelligence craze is blowing wildly throughout industry and society. Not only major global technology companies such as Google and Microsoft, but also domestic and foreign startups and large corporations are all focusing on releasing products and services using artificial intelligence.

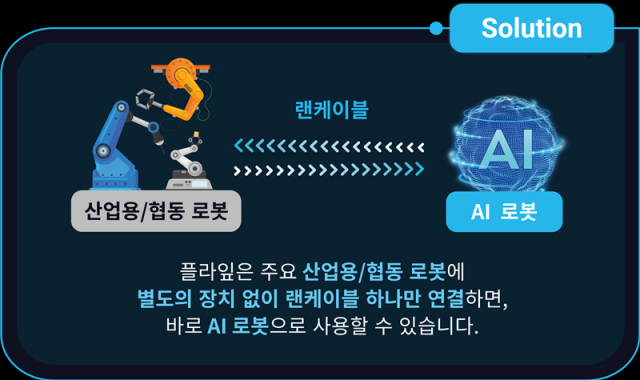

While large-scale language models such as GPT4.0 have sparked interest in on-screen AI, AI in robots that physically interact with the real world is also quietly evolving. Domestic AI robot startup Flyleaf recently took the first step in commercializing AI robot software that can be applied to industrial and collaborative robots.

Introducing the Flyleaf solution. source = leaf

Industrial/collaborative robots refer to robots that work on behalf of people and robots that work by helping people in industrial settings. Products in the form of robot arms found in factories fall into this category. These robots do not judge and move on their own, but mechanically repeat the motions input by engineers in advance. The task of teaching the robot to move is called teaching (teaching). In contrast, robots that have the ability to perceive the external environment through sensors, make their own judgments, and move independently are called AI robots.

Flyleaf’s AI robot software gives existing industrial and collaborative robots the ability and senses to judge on their own so they can be used as AI robots. The AI 3D Vision, recently developed by Flyleaf, is software that provides vision, among other things, and is the first step towards fully autonomous AI robots. Flyleaf will release two product groups: ‘PiC-Q’, which includes a 3D AI vision with camera and AI controller, and ‘Picus’, which also includes a robot and motion controller.

Flyleaf’s ‘Picus’ includes a 3D camera, robot arm, AI controller and motion controller. source = leaf

PickQ and Pickers are products that provide bin picking solutions that can be applied to existing industries and cooperatives. Bin picking refers to the task of picking up the desired object from a box containing many objects. Flyleaf applied deep learning to overcome several drawbacks and limitations of existing machine-based bin collection solutions.

Since the posture (6D) of an object can be estimated and recognized, stable and precise work can be achieved even in a work environment with irregular height or posture. In addition, even if multiple objects are mixed, it can be recognized smoothly, and processing speed and work success rate are increased by giving priority to objects that are easy to grasp because they are not covered or overlapped.

Pickers is a product that includes a robot arm and motion control software from Universal Robots as well as PickQ. In addition to the features of PickQ, it provides additional functions such as ‘push’. Pushing refers to the task of pushing an object to move its position or posture to a state where it can work when it is impossible for the robot arm to pick it up smoothly due to the posture or position of the object during empty picking.

In the past, it was possible to solve the problem simply using an additional device or shaking the box itself in an inefficient way with a robot arm. The problem of the camera not recognizing highly reflective parts, such as metal parts, was overcome by moving them to a location with less reflective light or changing their posture with a push movement.

The motion controller can be installed and used in the form of a plug-in to the teaching device (teaching pendant) of the robot arm, and it helps to control the robot arm more efficiently and conveniently. It is possible to realize functions that were difficult to use with existing robots, such as allowing the robot to find the best possible path for itself to move or detect collisions.

Windows GUI based AI 3D vision platform software. source = leaf

By using Pickers and PickQ, existing robot teaching process can be replaced with AI, so complex and difficult installation or maintenance problems can be solved, Flyleaf explains. You can set the robot’s operation or monitor its status in an intuitive window-based graphical user interface (GUI) environment without the need for robot programming. He also emphasized that the cost of delivery is low compared to other solutions in the same class because AI can perform advanced tasks without additional facilities or expensive equipment through learning.

Flyleaf expects that Pickers and PickQ can be used not only in areas where machine vision based bin picking has been done, such as manufacturing and distribution centres, but also in areas where it has been difficult to use them due to technology limitations in the past. . Flyleaf CEO Jeong Tae-young said, “With the release of PickQ and Pickers, we have introduced innovative technologies in the field of autonomous robot arm.” “The development of autonomous robot arm technology will have a positive impact not only on the manufacturing, logistics, and service industries, but also on our daily lives. . Flyleaf will continue to make continuous efforts to develop technology that will lead to these changes in life.”

Donga.com IT expert Kwon Taek-gyeong, reporter tk@itdonga.com