As the switch to environmentally friendly refrigerants becomes a global regulation, ultra-low temperature refrigerant technology is being developed using natural refrigerants, which has emerged as an alternative.

The Korea Energy Technology Evaluation and Planning Institute recently announced ‘Development of ultra-low temperature refrigeration equipment technology at -100℃ level using natural refrigerant’ as a new research and development task for the 2024 energy technology development project.

Cryogenic refrigeration equipment used in semiconductors, pharmaceuticals, and hydrogen charging stations, which are strategic industries in the future, have a high operating cost burden (including energy cost) on the industry, so the demand for efficiency technology high increases rapidly. According to Fortune business insights research data, cryogenic equipment is expected to grow at an average annual rate of 8.9% from $17.24 billion in 2020 to $32.86 billion in 2028.

In addition, there is a need to develop cryogenic technology based on air coolers that are environmentally friendly and can improve efficiency, reliability and cost-effectiveness at the same time. The technology of cryogenic refrigeration equipment is a very difficult technology, so there are limitations to the independent development of companies, so the government’s research and development support is needed.

It is a next-generation cold and heat supply technology that is currently owned by three leading global companies, including Mitsubishi Heavy Industries, Mayekawa, and Mirai Intex. In the case of Korea, the development of technology to implement the principles of the cold air refrigeration system into very low temperature cold and heat supply equipment was promoted starting in 2002, earlier than in Japan, but the overall technological maturity (technology bearing, high- speed motor, etc.) at the time problematic.

In particular, HCFC refrigerants in the current refrigeration industry are expected to be completely phased out by 2030, and HFC refrigerants also have a GWP of 1,500 to 3,800, meaning they cannot be used in the medium to long term . Accordingly, there is an urgent need to prepare a preventive policy and technical alternatives using low GWP natural refrigerant refrigeration technology.

The total cost of supporting and developing this project is 18 billion, including about 4 billion earned in research and development costs supported by the government in the first year, and the final goal is to develop a -100℃ refrigeration system using refrigerators natural to use. in industrial processes and performing performance tests.

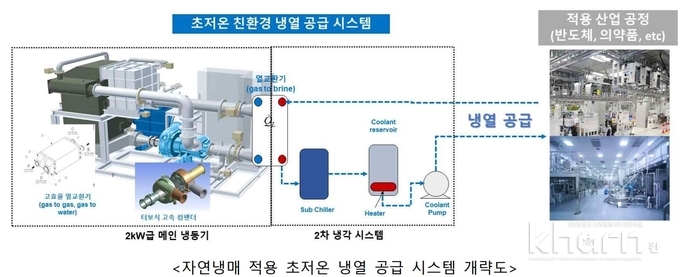

To this end, in order to develop a main refrigeration system with a cold heat supply capacity of 2kW for industrial processes, △ apply the reverse Brayton refrigeration cycle △ develop a turbo-type compressor, expander, and heat exchanger △ develop a process -cooling system related secondary △ performance tests and simulation experiments of the application process Scale test evaluation △ Propose measures to ensure reliability for verification.

In addition, △ integrated design of high-speed turbo compander and heat exchange system, optimal refrigeration operation technology △ complex cycling system technology for ultra-low temperature operation △ ultra-low temperature refrigeration system operation technology (integrated technology for temperature maintenance , the safety and reliability of turbo devices, application process connection, etc.) △ Refrigeration system packaging technology, technology to ensure the reliability of high-speed operation equipment, the development of an integrated system of the main refrigeration system and the secondary cooling system, and oil operation -It less equipment with oil-free bearings in progress, and equipment performance test evaluation must be implemented in response to the needs of the industrial process to be applied (real-scale operation time (more than 100 hours).

#Development #temperature #cooling #heating #facility #technology #natural #refrigerant